The Sustainable Village is a testbed for experimental building technologies

that brings the vast challenges of cold climate housing to the doorstep of

the research center. Each house has a unique combination of foundation,

wall assembly, and heating and ventilation strategies so we can learn more

about the cost-benefits of each.

The insulated raft appears to be an economical foundation on permafrost,

costing $10,000 less in materials than conventional permafrost

foundations. We are studying the long-term impact of the raft foundation

on ground stability and testing a passive cooling feature built into the

design as part of a comprehensive monitoring program.

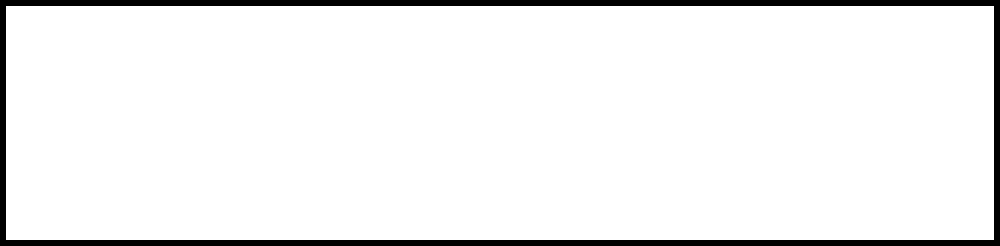

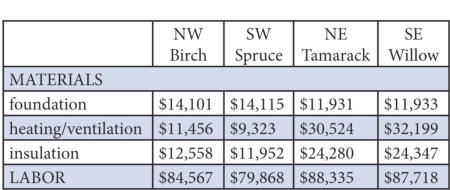

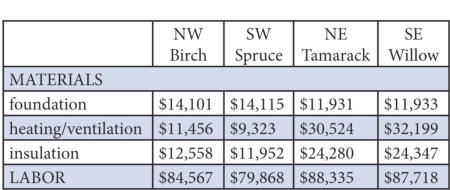

A new economic analysis shows the cost of various systems used in the

Village, just the beginning of what we will learn about building science and

affordable construction from the project. The Spruce house was less

expensive than the Tamarack house, for instance, largely because the

foundation and mechanical systems cost less than their counterparts in

other homes.

Spruce used a polyurethane foam raft foundation reinforced with steel

joists that thermally isolated the house from the ground. Heating and

ventilation is provided by an HRV system with a small inline diesel heater.

The most expensive house was Tamarack, which sits on pilings and is

heated with solar hydronic and a high efficiency oil hot water heater.

CCHRC is monitoring the energy and economic performance of all the

homes, and the fuel savings and payback of the solar installation will be

calculated at the end of the year.

Another big takeaway is the roughly equal cost (both in material and labor)

of the two wall variations: a REMOTE wall with 8 inches of exterior foam

and a REMOTE wall with a standoff wall and 12 inches of exterior cellulose

insulation.

The numbers will paint a detailed picture of the options and tradeoffs of

affordable, energy efficient construction.

Foundation and mechanical systems were the biggest cost factors in the four Village homes.

Foundation and mechanical systems were the biggest cost factors in the four Village homes.

The UAF

Sustainable

Village

The UAF

Sustainable

Village

Foundation and mechanical systems were the biggest cost factors in the four Village homes.

Foundation and mechanical systems were the biggest cost factors in the four Village homes.

The UAF

Sustainable

Village

The UAF

Sustainable

Village